05:00

Bamboo scaffolding: why Hong Kong is among the last cities using centuries-old building method

Explainer | Why Hong Kong still uses bamboo scaffolding in construction

- Everything you need to know about a material that is flexible, strong and cheaper than steel and aluminium

- Bamboo scaffolding doesn’t require sophisticated machinery or complex tools to erect, just skilled - and brave - workers with nylon ties

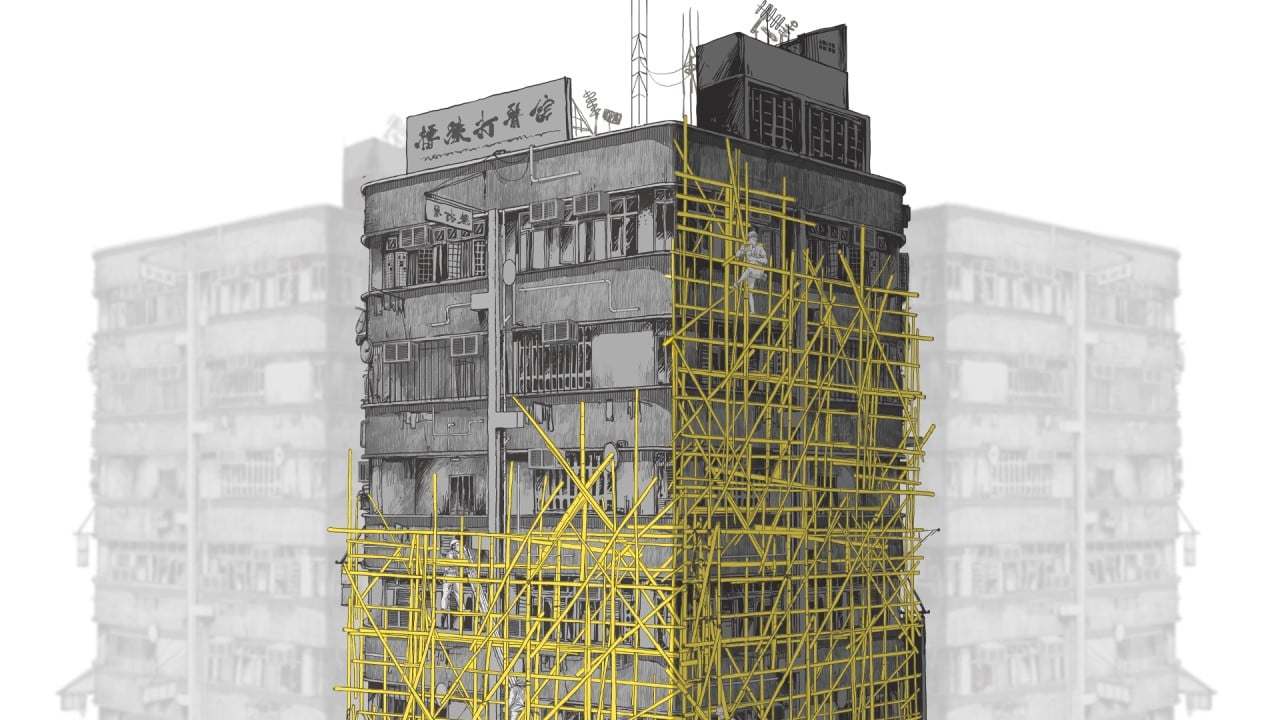

Hong Kong is one of the last places in the world where bamboo is still widely used for scaffolding in construction. It’s flexible, strong and cheaper than steel and aluminium — metal alternatives that are now more commonly used in mainland China and elsewhere in Asia.

In Hong Kong, skilled armies of scaffolders can erect enough bamboo to engulf a building in a day — even hours — using techniques that are thousands of years old, and have been passed down through generations.

How long has bamboo been used in construction?

Throughout Chinese history, bamboo has been widely used in construction. Bamboo scaffolding can be seen in one of China’s most treasured works of art, Along the River During the Qingming Festival. The piece, by imperial artist Zhang Zeduan (1085-1145), is famous for its depiction of day-to-day street life along the Bian River in Bianjing, which was the capital of the Northern Song dynasty.

Why bamboo?

Bamboo is one of the fastest-growing plants in the world, and in some cases can grow 60cm a day, and eventually 40 metres tall. Bamboo has thick underground roots called rhizomes, which can grow quickly, creating new shoots metres away. Bamboo’s internal cell-like structure allows it to withstand compression, making it an ideal material for scaffolding.

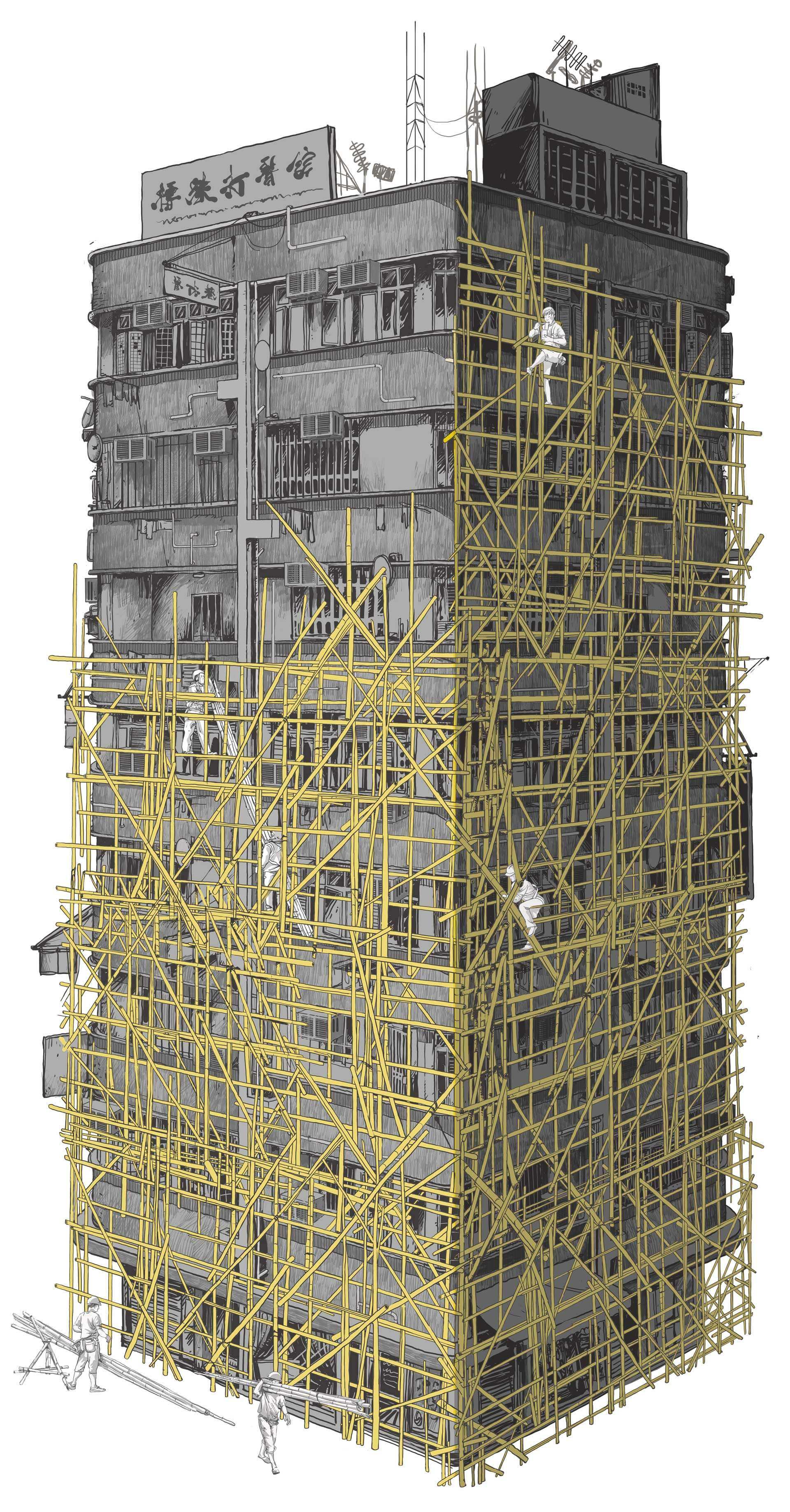

Compared to steel, bamboo is much lighter, six times faster to erect and 12 times faster to dismantle. It’s also a fraction of the cost. Bamboo scaffolding doesn’t require sophisticated machinery or complex tools to erect, just skilled workers with nylon ties. If properly erected, bamboo scaffolding can be stronger than steel and far more flexible. The resulting structure is also easy to modify, if necessary. Bamboo scaffolding can be used for entire structures, or part of them. In Hong Kong it is common to see “bamboo balconies” jutting from the sides of buildings where renovations are being carried out on individual units, many floors up. A bamboo pole can also be cut to fit an awkward space, which is ideal for Hong Kong, where construction spaces can be tight amid the densely packed maze of buildings.

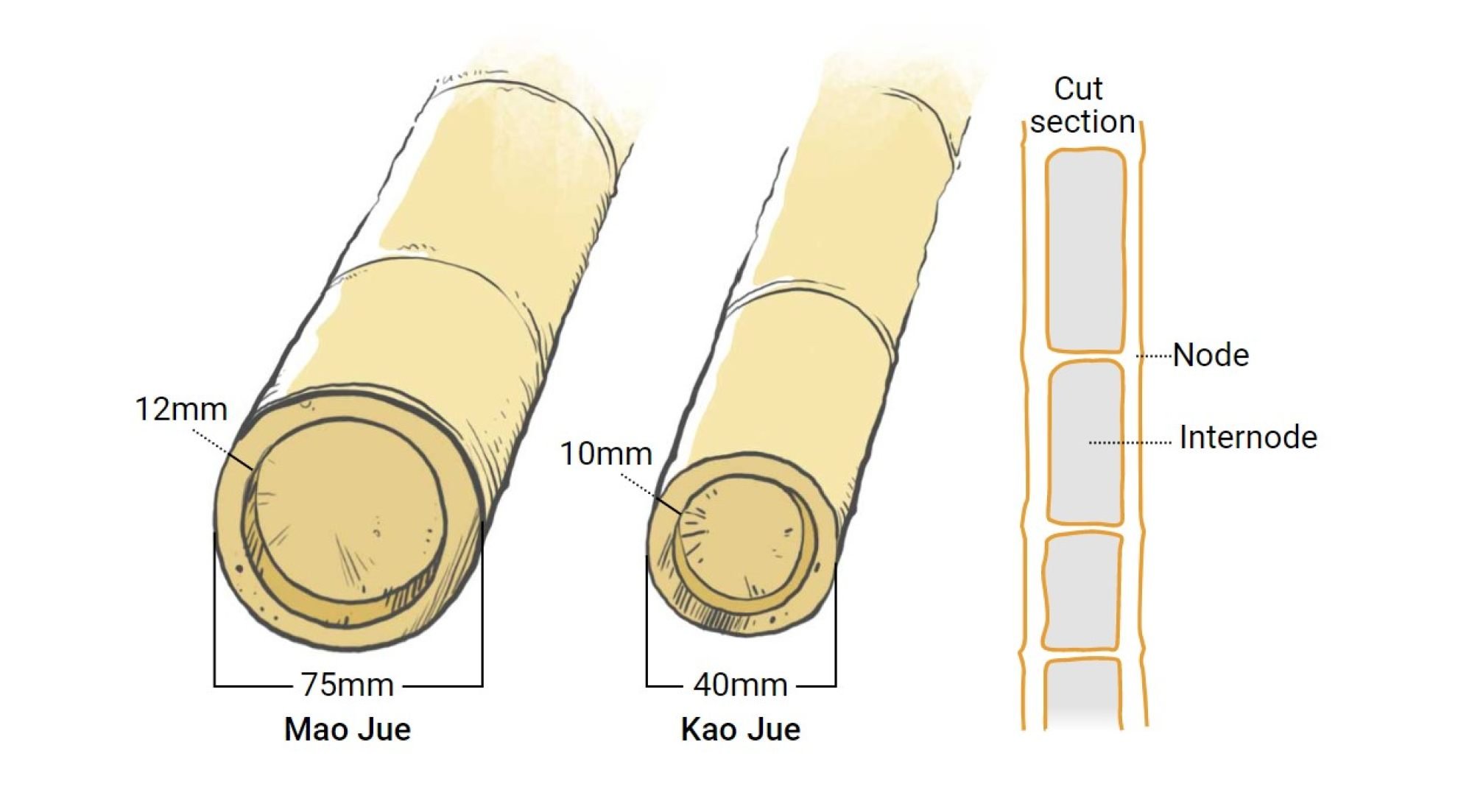

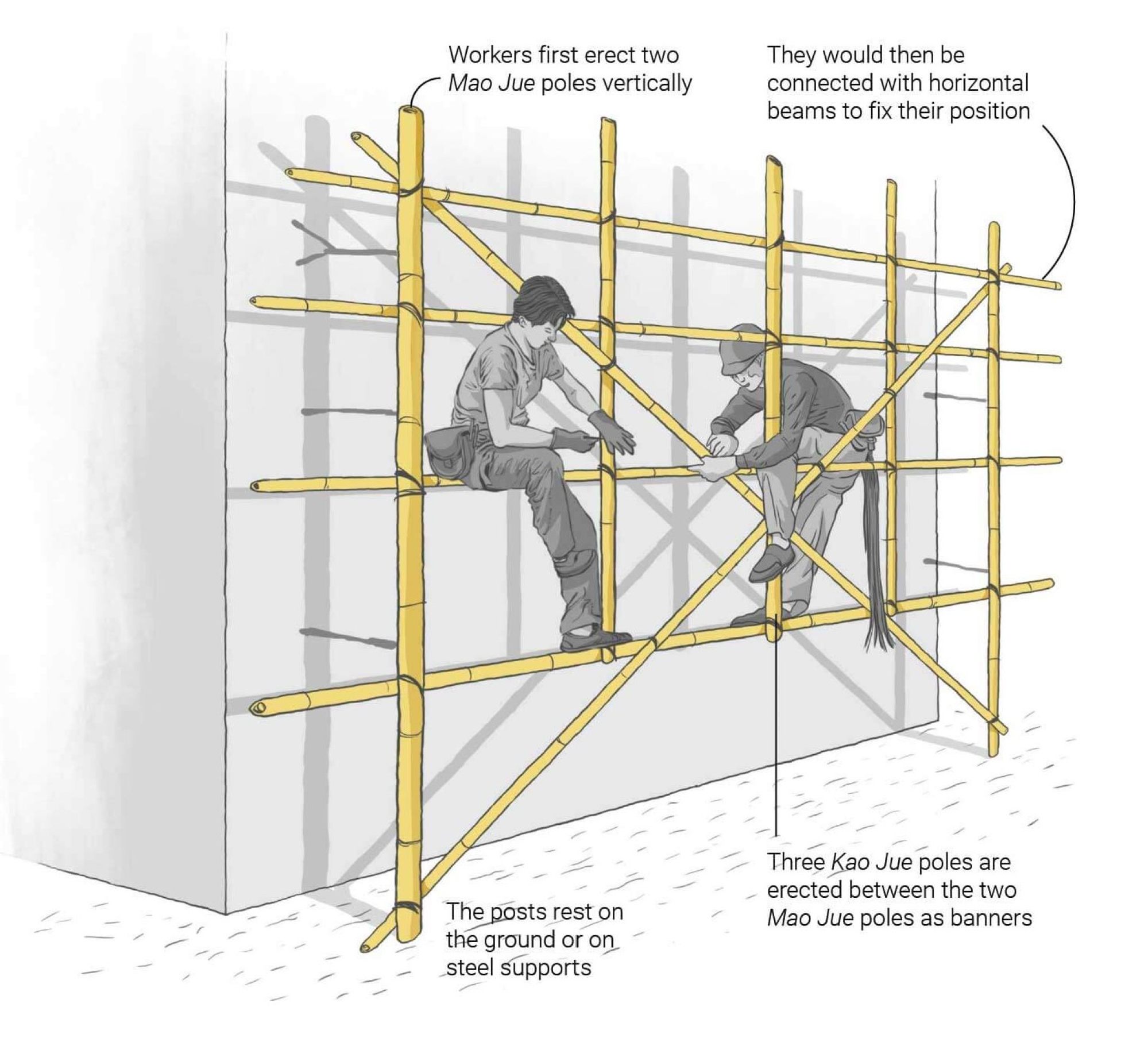

In Hong Kong, two types of bamboo are used in most scaffolding: Kao Jue (pole bamboo) and Mao Jue (hair bamboo). Mao Jue is thicker and stronger, about 75mm in diameter, with walls at least 10mm thick. It is used as the load-bearing support. Kao Jue is thinner, about 40mm wide, and is used for platforms, bracing and horizontal support. All bamboo is at least three years old, and dried for at least three months. Each piece is about seven metres long, can be stored in the open, and typically usable three times before it starts to bend, split and weaken.

Who are the scaffolders who climb bamboo?

They are Hong Kong’s real-life spider-men, climbing dizzying heights with strength, skill and nerves of steel. But the future of the bamboo scaffolder business remains precarious, due partly to a lack of new blood as many turn to other construction areas such as bar bending. Today, there are 2,479 registered bamboo scaffolders in Hong Kong.

Requirements for safe, sturdy scaffolding:

-

Bamboo scaffolding should be erected, altered and dismantled only by trained workers

-

Erection of structures should start from the bottom level to the top, from interior to exterior

-

Working platforms should be at least 40cm wide, free of loose debris, and not overloaded

-

A protective screen of fire retardant material must be installed to confine falling objects

Then and now

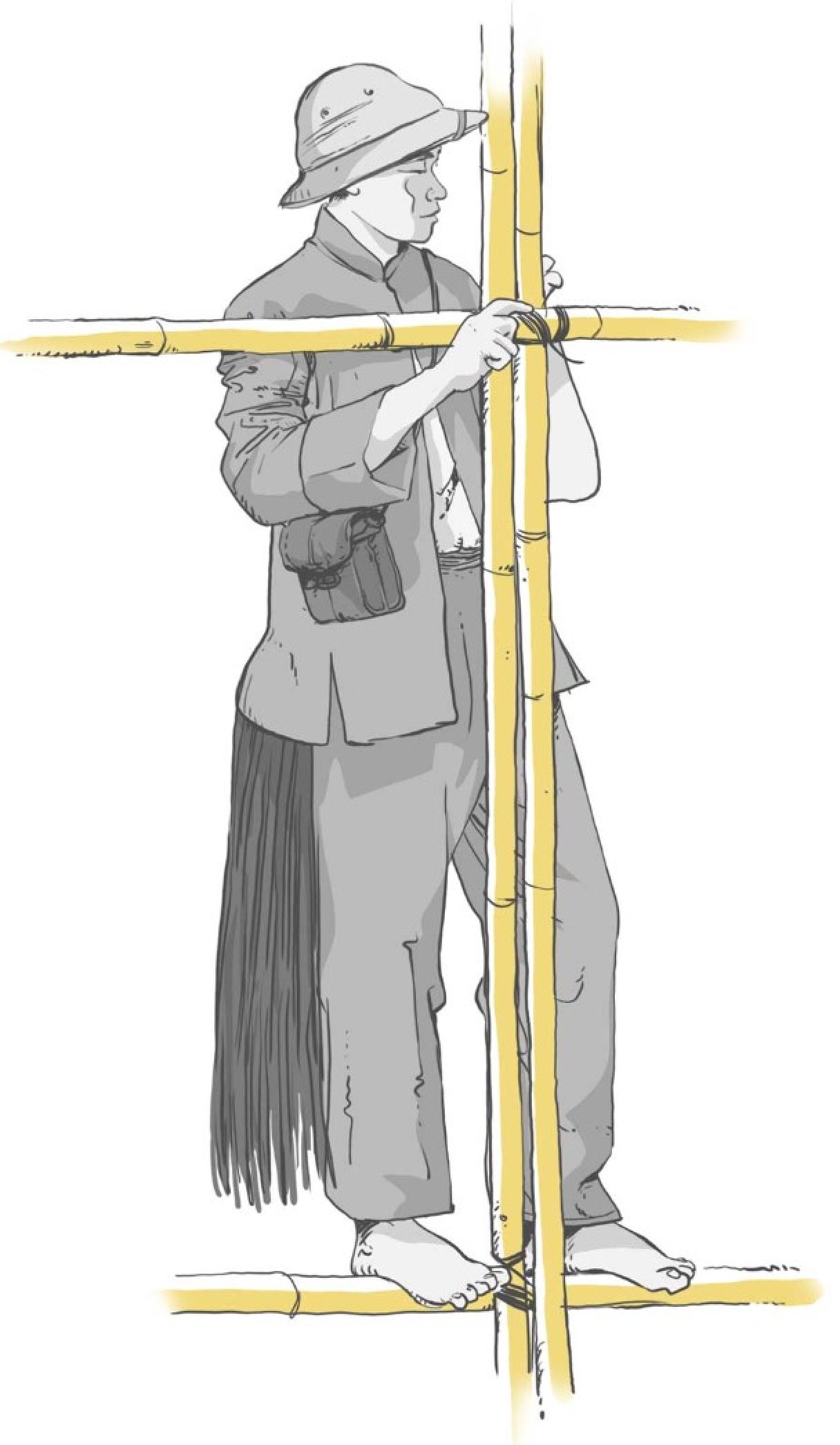

Many decades ago in Hong Kong, bamboo scaffolders worked at heights with basic safety harnesses, or none at all. Much has changed since then and workers today must be trained, licensed and wear proper safety gear.

In the past, scaffolders would typically wear clothing for comfort and easier mobility - a straw hat for sun protection, a basic T-shirt or tangsam, kung fu pants, a basic safety belt (if any), and sometimes, no shoes for easier climbing.

These days, a scaffolder’s belt carries a bundle of nylon strips, which are used to secure bamboo poles. Workers also carry a small bag with tools, including a knife.

Required protective equipment includes:

Safety belts: Must be worn at all times. Scaffolders normally use full body harnesses, which should be attached to anchorages

Hard hat: Must be worn at all times to protect heads from falling debris

Protective sleeves: These offer cover from the sun, and help protect arms from sharp surfaces while working

Gloves: To protect hands from injuries such as splinters, and provide grip for climbing

Safety shoes: They must be firm and have a non-slip sole

Scaffolding must come down as soon as construction or repair work is completed, according to Hong Kong regulations. To reduce risk of mishaps, dismantling should be carried out by “trained workmen under the immediate supervision of a competent person”, ideally the crew that erected the structure.

Are bamboo scaffolders licensed?

Many scaffolding skills have been passed down from masters to apprentices over hundreds of years. Today in Hong Kong, most new recruits must undergo year-long training with the Hong Kong Construction Industry Council for a licence.

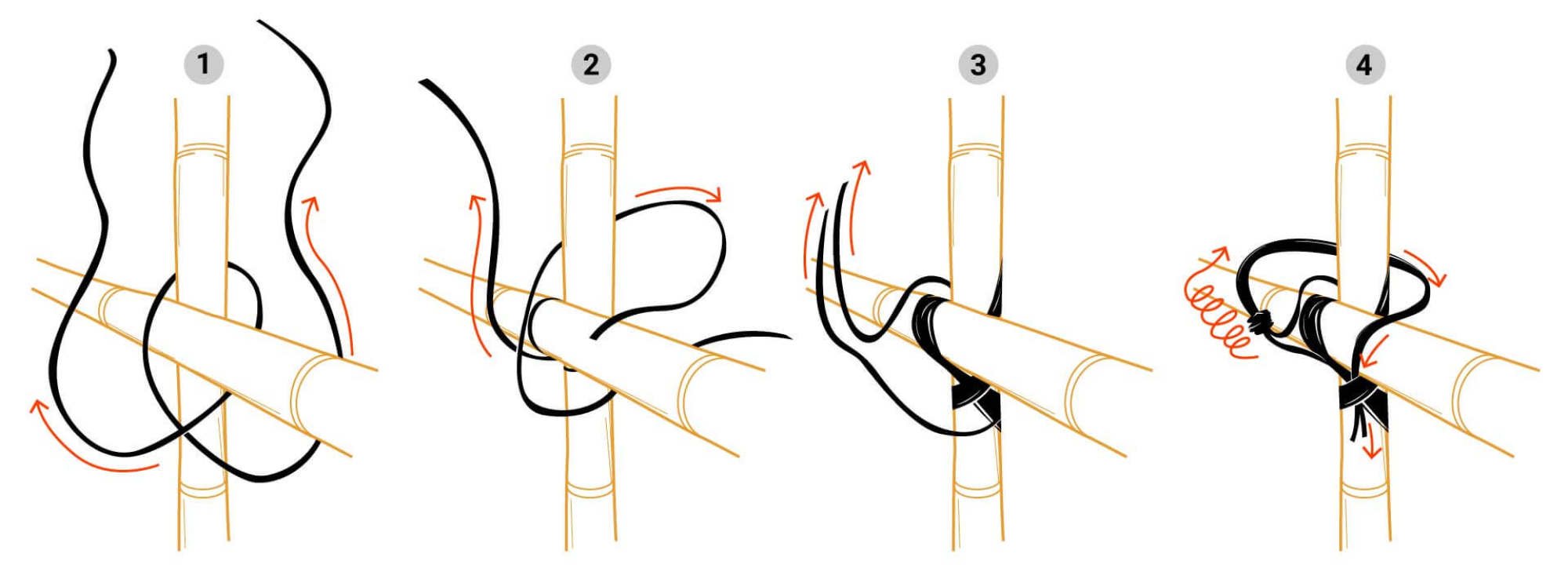

Training involves learning how to build bamboo platforms that are safe and strong enough to hold construction workers on all different imaginable sites. The toughest part of the job, though, is tying a proper knot to secure bamboo poles, which can take years to master.

Workers are typically divided into three ranks. Those new to the industry are apprentices for two years. They have basic tasks, such as passing bamboo poles, while also learning the trade. Those in the middle rank erect bamboo scaffolding while being supervised by masters — the highest rank — who work with engineers to design entire structures. Pay varies, depending on experience, from about HK$800 (US$101) a day to more than HK$2,000 a day (US$254).

Tradition calls for an apprentice scaffolder to discover if he is at risk of misfortune. If so, a feng shui master may recommend a ceremony to help cast out negative influences. Before work each morning, an apprentice should also be mindful about what he says so there are no bad omens for him and his workmates.

Workers sometimes worship deities and wear a special belt that supposedly protects them from bad luck. It’s not uncommon for scaffolders to do a bai san ceremony for good fortune before erecting scaffolding at new sites.

What types of bamboo scaffolding are there?

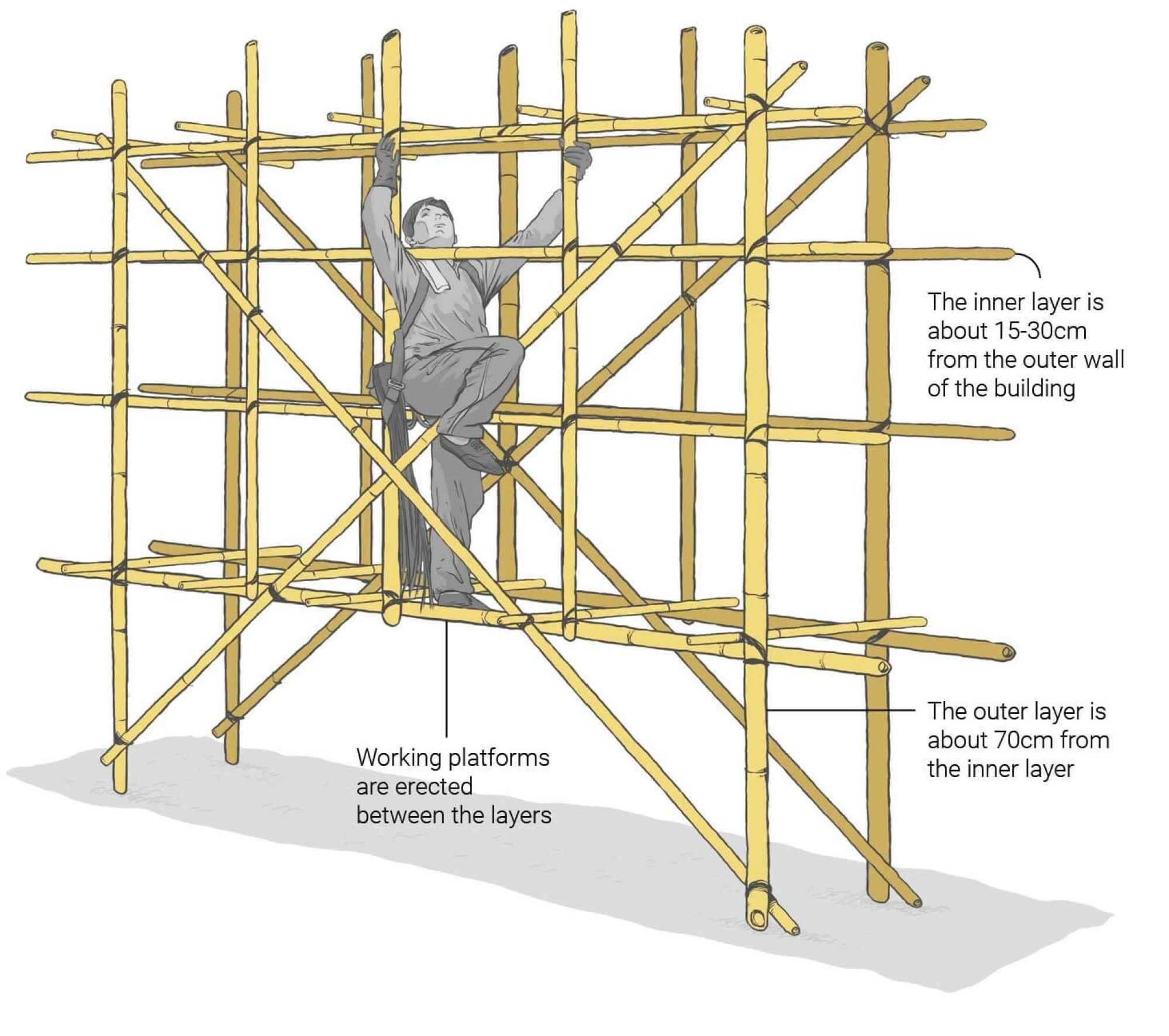

1. Double- or single-layered bamboo scaffolding

This is for building construction or major renovations.

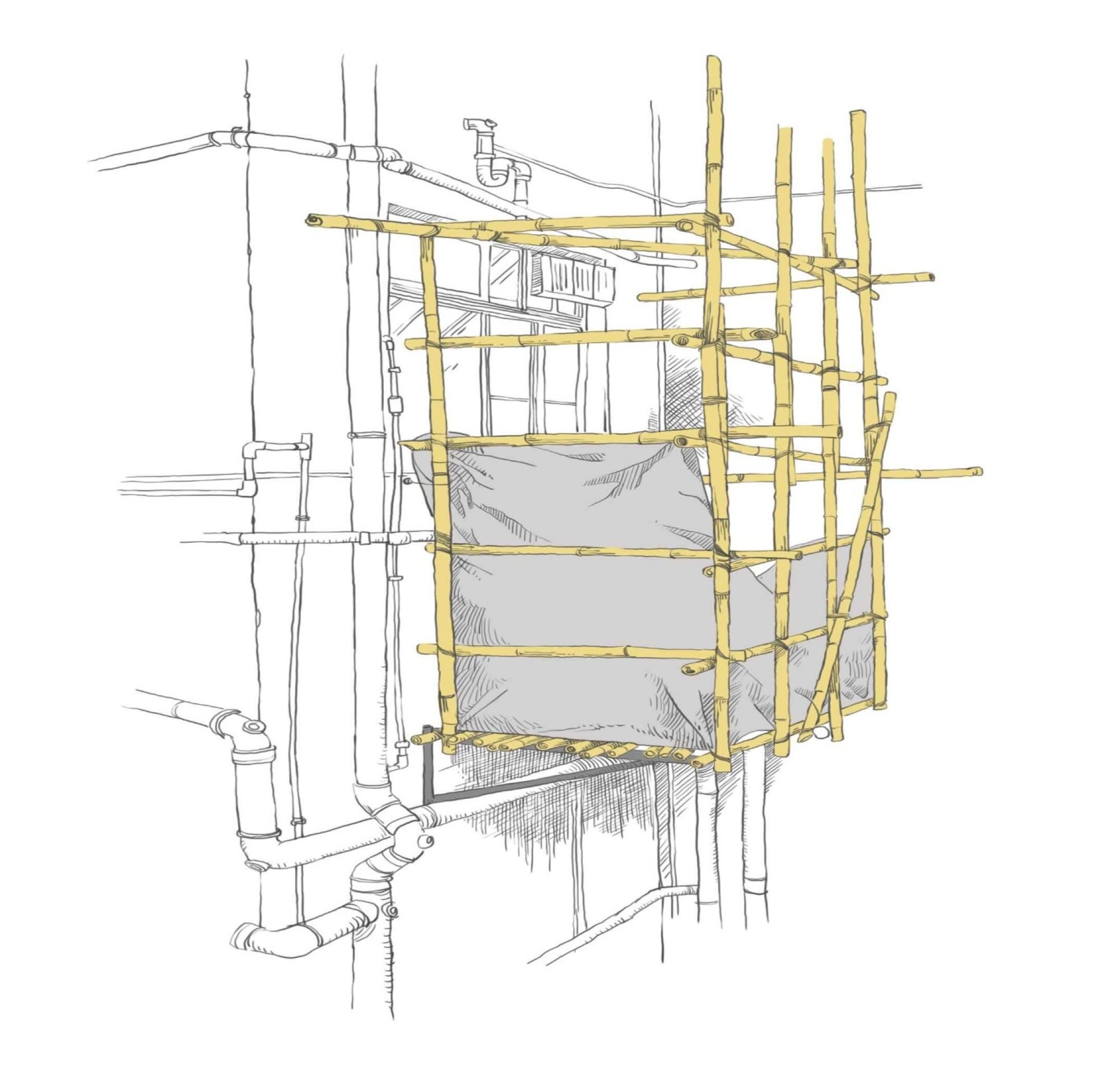

2. Truss-out bamboo scaffolding

This is often used as an exterior platform for minor repair work of external drain pipes, spalling concrete and external rendering. The height of the scaffolding should not exceed six metres.

3. Bamboo scaffolding for signboards

They are typically of cantilever construction with a maximum 4:3 length-to-height ratio. The entire scaffold is supported by steel wires or hanging posts attached to the structural elements of a building.

Regardless of type, bamboo scaffolding should be dismantled from the upper level to the lowest level, from the outside to the inside, and non-load-bearing parts before load-bearing parts.